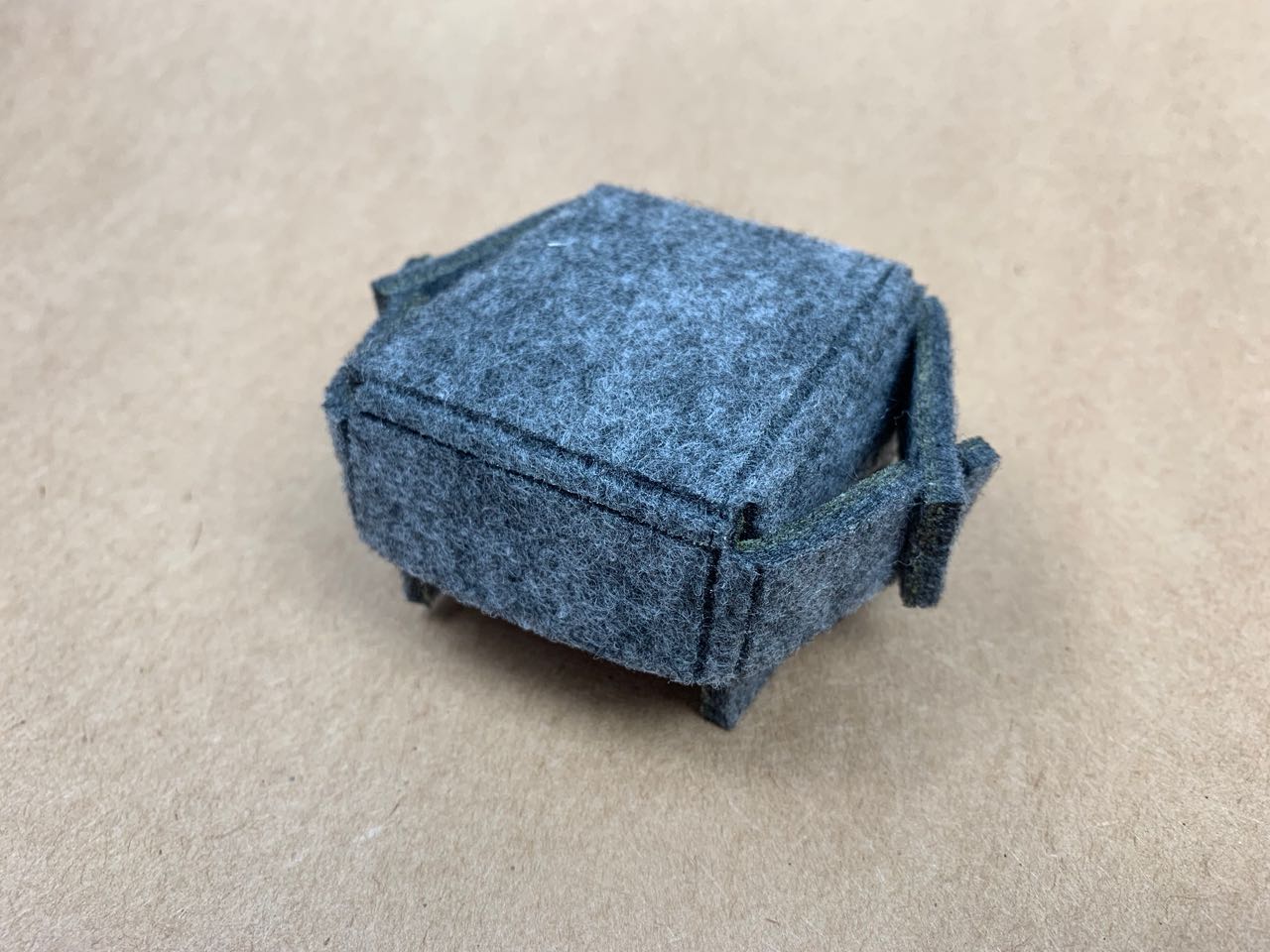

soft-fabrication

Felt — Cutting and Scoring

I’ve tried some different settings on the Fablab’s Epilog Helix laser cutter.

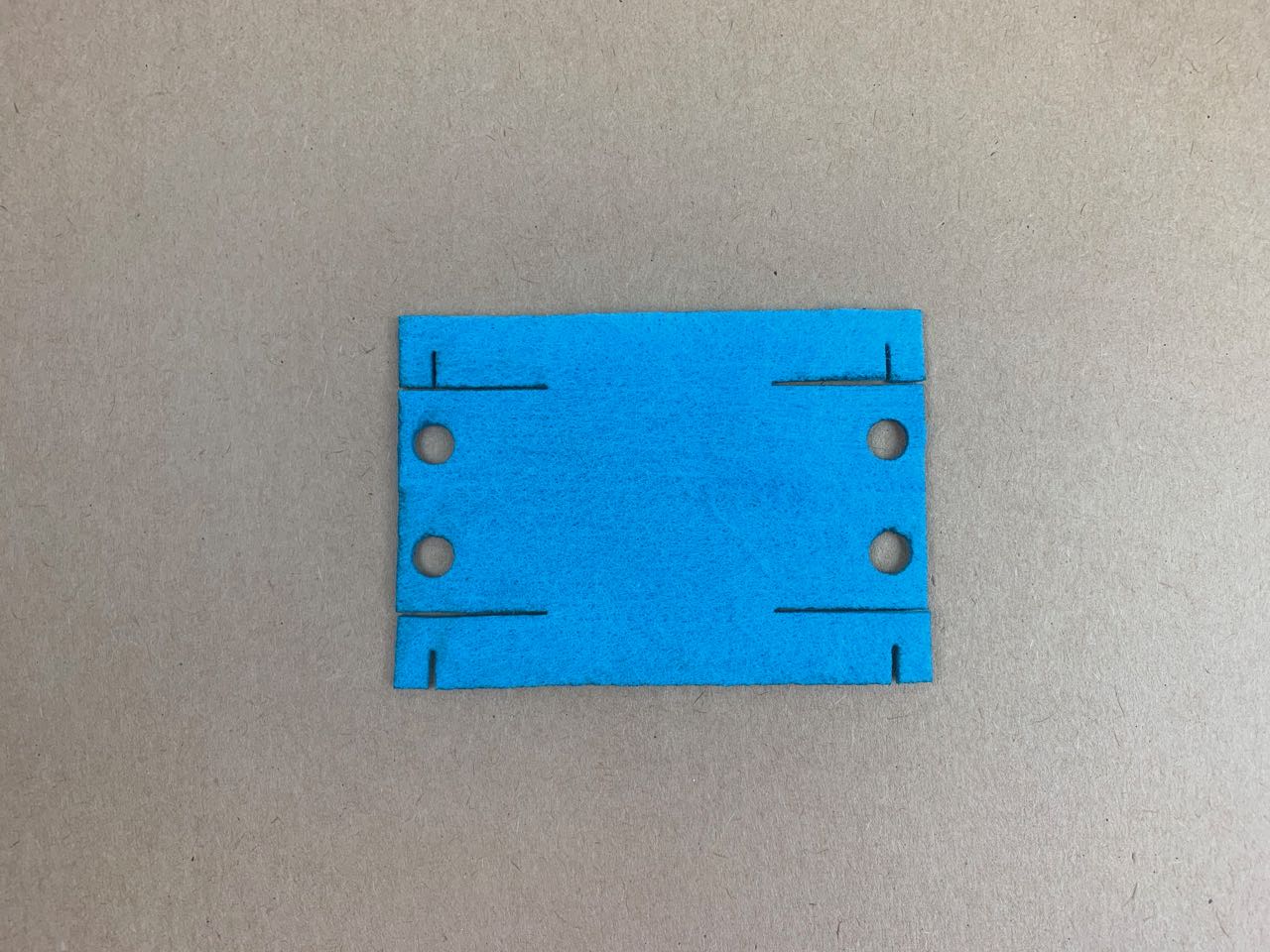

Thin Acrylic Felt (approx. 1-2 mm)

Cutting

| Speed | 100 % |

| Power | 50 % |

| Frequency | 5000 Hz |

This gives about about 1 mm of kerf. Some mild scorching on edges, but not too bad. Small features (e.g. 1 mm across) are lost dues to melting from the laser passing over the same place twice.

Scoring

| Speed | 100 % |

| Power | 5 % |

| Frequency | 5000 Hz |

For material this thin, scoring isn’t really necessary, but this setting worked fine.

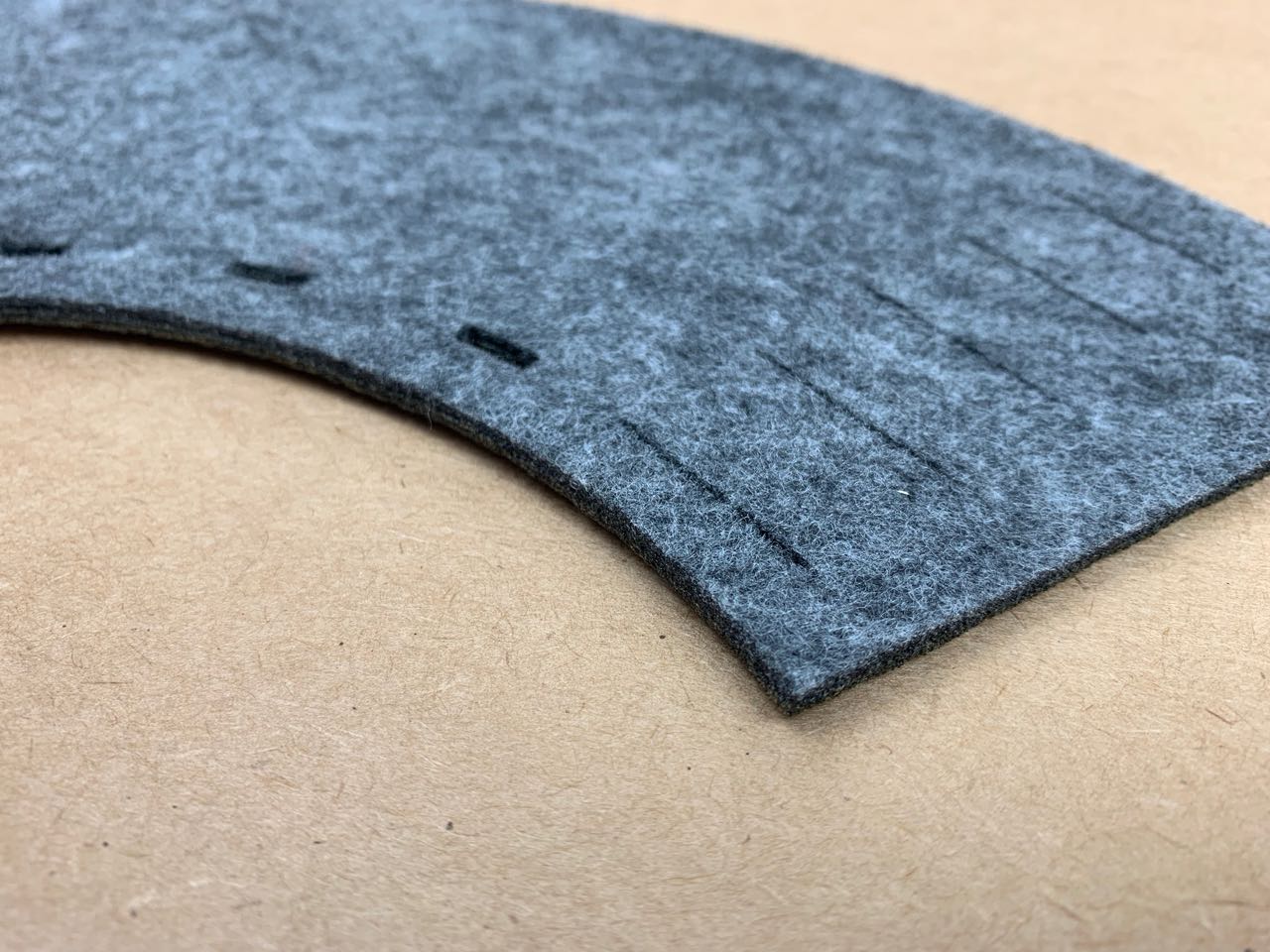

Thick Soft Acrylic Felt (5 mm)

Cutting

| Speed | 100 % |

| Power | 70-90 % |

| Frequency | 5000 Hz |

This gives quite a good edge, but there is some roughness from the uneven melting. It might be worth experimenting with slower speeds.

Small features (e.g. 1 mm across) are lost dues to melting from the laser passing over the same place twice.

Also works:

| Speed | 50 % |

| Power | 30 % |

| Frequency | 5000 Hz |

(Imperceptible difference in quality)

Scoring

| Speed | 100 % |

| Power | 10-15 % |

| Frequency | 5000 Hz |

Thick Stiffened Acrylic Felt (5 mm)

The same settings as for the soft 5 mm felt worked, but there was some discolouration of the felt from the stiffening agent.

Smell

All the cut pieces smell terrible. I’m waiting to see if this fades over time. It would be interesting to compare with wool felt.