Pen case

I recently made this pen(cil) case, for reasons outlined elsewhere, and decided to document the process. I think this would make a great first project for someone who is new to sewing and wants to make something useful and ‘technical’.

Update: November 2013. Flickr seems to be randomly deleting photos, so I’ve removed the hot-linked images and replaced them with directly embedded versions. You can still see the full photo set (I hope) on Flickr.

Why you should make this case

If you’re new-ish to sewing, this is a great project to try

- It is essentially a 2D object: that means no tricky 3-dimensional corners to sew into. And the ordering of construction is pretty straightforward

- You don’t even need to sew round any corners. It’s all straight lines.

- It can be made with man-made, coated fabrics. That means they don’t stretch, and don’t fray. You can measure, cut and handle them with a high level of precision

- Everything is adaptable: fabrics, design, measurements: all can be changed to suit you

- It’s small and manageable. The biggest piece of fabric is about the size of a sheet of A4/letter paper. Super easy to handle.

Materials

I used cheap PU-coated (waterproof) ripstop nylon for the lining and pockets. It’s about £4/m. I used much heavier coated Cordura (about £8/m) for the outer casing, which is probably overkill.

I also used some 25mm wide grosgrain ribbon, which is dirt cheap and you can buy from any haberdashery.

Also some standard velcro ‘hook and loop’ fastener, although wider velcro would be better, and one metal popper.

Most of this was left over from other projects, both lightweight backpacking rucksack. If you want to read more about the fabrics, and how to get them, check that project writeup.

Let’s go!

Step 1: Planning

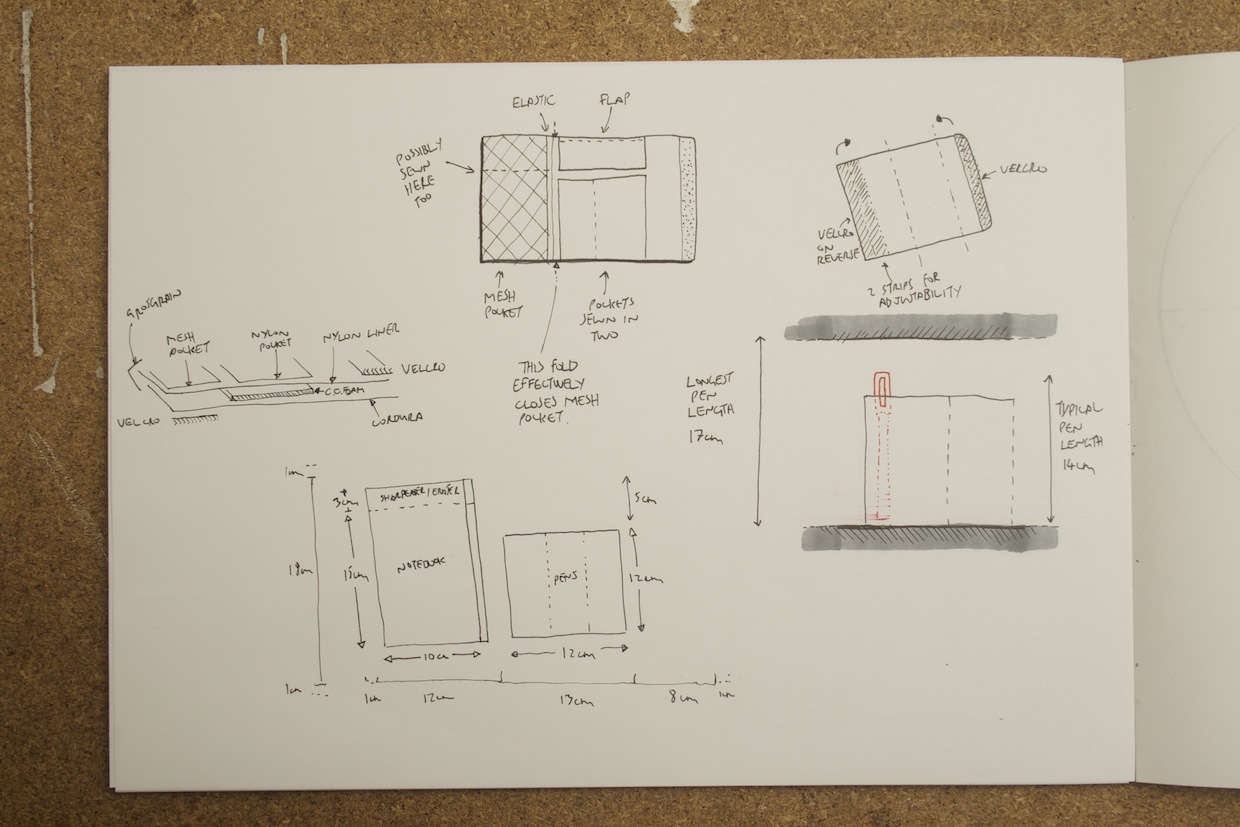

The design for this case is inspired by simple folded cases like the Alter Manufacturing Mod.02 and the Nomadic PE-10 Tri-Fold case.

I wanted to make a simple case and these kinds of flat folded cases looked like a good starting point. So I looked at my current pens and other bits and pieces and started to sketch out what might work for me. I also started to think about construction, and how all the components could be assembled and in what order.

Step 2: Prototype

I sewed up a quick prototype in scrap cotton to test a few ideas out, and verify the design I’d planned out. Moving into a 3D prototype helps answer some important questions, such as:

- How will the pockets deform when they’re filled with pens? How many pens can you fit in?

- Will the pen clips work? How will the pockets accommodate different length pens

- How will the case behave when folded closed? Will the pens fall out?

- What’s the best way to edge a pocket? Do the corners need to be reinforced?

- Will pockets with wide openings keep their contents secure?

- What kind of materials work for lining, outer casing, trim and padding?

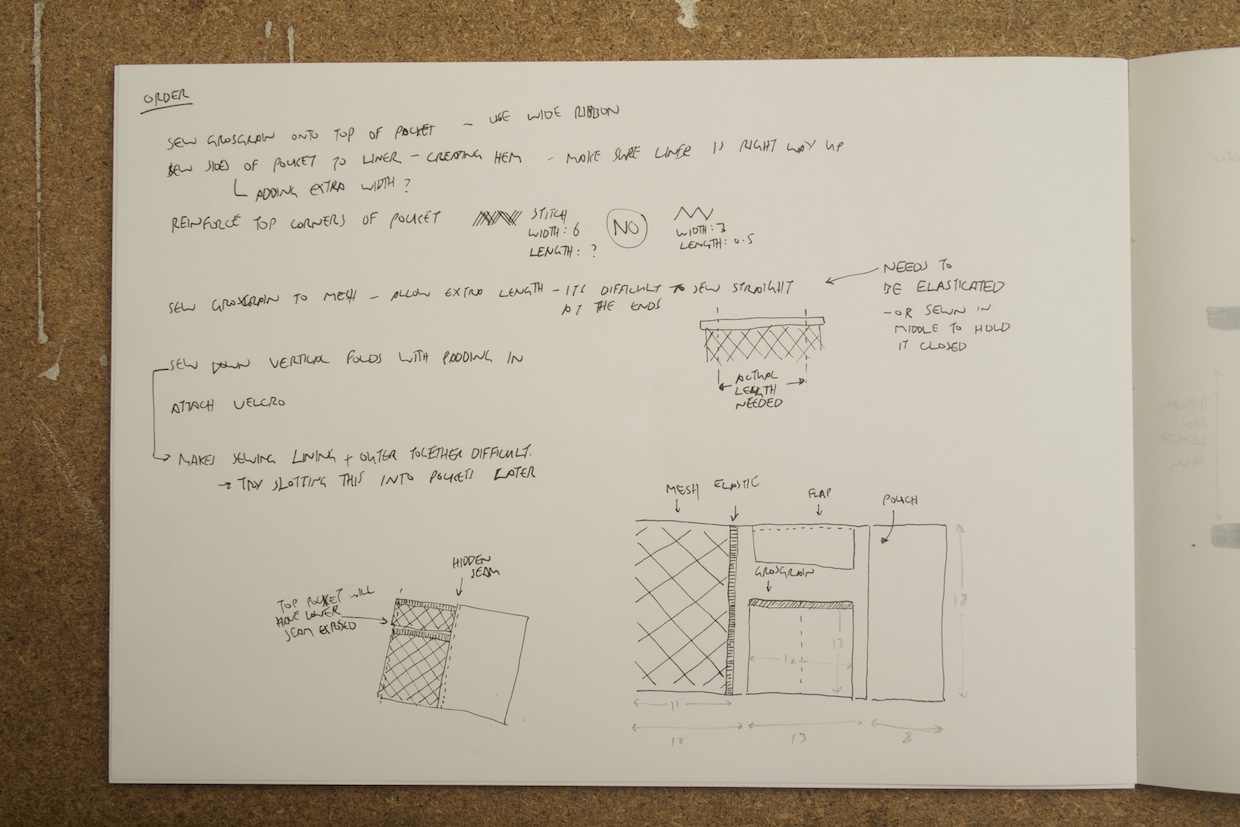

After making my prototype, I made several improvements to my original design:

- I had intended to use some thin closed cell foam to cushion the pens. This made accurate sewing difficult, so I ditched it.

- I originally included one large mesh pocket that could accommodate a memo book or more pens. But this proved to be insecure in use, with nothing to stop the contents from just sliding out. If I’d been making a more rigid case, I could have used elasticated edging to keep the pocket closed, but I decided to ditch this pocket and make a secondary pocket behind the main pen pocket to hold a pad, and two smaller additional pockets on the side each with a different closing mechanism (detailed later).

As I was making the prototype, I kept notes on the order of construction, and any problems I’d encountered. In particular, I noted which elements had to be assembled first – this is critical in any layered project. For example, you have to sew the pockets onto the lining before attaching the lining to the outer shell. Otherwise, your stitching shows through on the outside.

I also made a small prototype pocket using the actual lining material I was planning on using, to test a different technique for edging the pocket (rolling over the fabric, rather than lining with grosgrain ribbon) and try out different reinforcing stitches. I also wanted to see how the pockets deformed when full, and work out if I needed to add any pleats to accommodate pens. Fortunately I didn’t, though it is worth noting that without pleats, a 10cm wide pocket is more like 8cm wide once it’s full of pens.

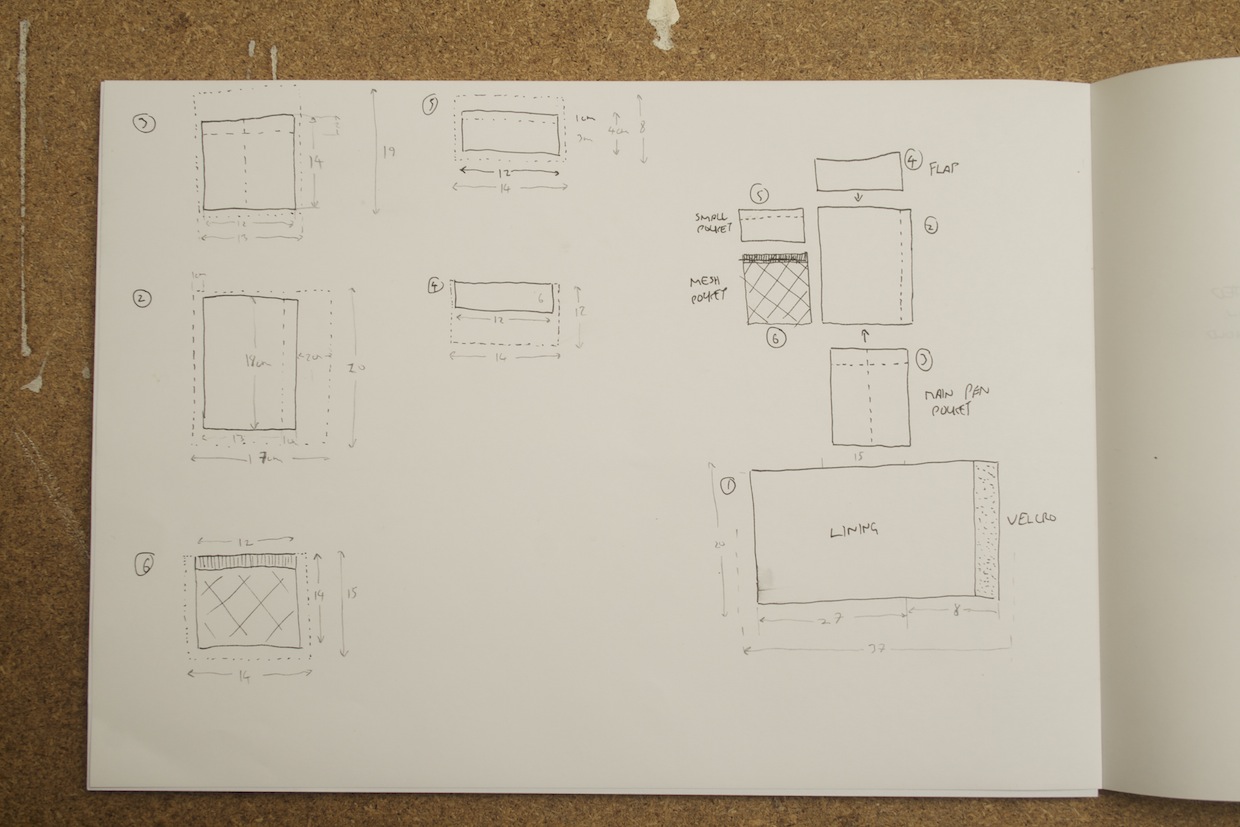

Step 3: Revised plan and cutting

Having figured out all the changes I wanted to make, I mapped out the whole case , how big each piece of fabric need to be (allowing for seams and rolled pocket edges where necessary) and marked and cut the fabric for each piece.

Step 4: Make interior pockets

Now onto the sewing. I made each of the pockets as individual items, then attached each of them onto the lining. First up was the main pen pocket. This image shows the reverse of the fabric with the PU coating, and the rolled and stitched top.

Then I made the two smaller pockets for the left flap of the case, and the large notepad pocket that sits behind the main pen pocket. Each pocket has one finished side (the side that will eventually be the pocket opening). All of the ripstop nylon pockets have rolled and stitched openings. The mesh pocket uses a length of 25mm grosgrain ribbon.

The other sides can be left raw as they will be stitched into the body of the case. The exception is the bottom edge of the smallest pocket, This edge will be visible on the finished case and so it needs to be hemmed.

Step 5: Interior assembly

Start by attaching the two small side pockets to the notepad pocket. This will give you a clean seam for these three pockets when opened out. Remember to place the pieces face to face (‘right sides together’ I think is how the pro’s say it) and pin them before sewing your seam.

Then it’s time attach the main pen pocket to the notepad pocket. Sew the right edge in the normal way (both pieces face-to-face, sew a seam, then flip the pen pocket back so it’s in the final orientation and sew over that seam 2mm in to finish the right edge. On the left side, you need to cheat a bit, as you can no longer place the pieces face-to-face. So fold the left edge over by your seam allowance (I used about 5mm on these pieces), tucking it under the pocket. Pin it and sew up the left edge again, 2mm in from the edge. Then sew up the middle of the pocket to split it into two.

This photo also shows the two small pockets on the left attached and folded back into their final position. And I’ve made and attached a flap to help keep the pens in place when the case is thrown in a bag. This flap is made in the classic style. Take a piece of fabric twice the height of the flap. Fold it along its width (outside faces together) and sew up each side. Trim the corners off on the folded edge, turn the pocket right way out and sew along the three finished edges about 5mm in to leave you with a nice flat piece.

A few bits of detailing: I also used a small zigzag stitch on the top of the pocket to reinforce the opening.

I sewed a small zigzag stitch in the middle of the smallest pocket to make it more secure.

I hand-stitched a popper to the mesh pocket so it could still be used to hold wide items but with the popper closed would again be more secure. You can see I should have used black thread. Shoddy.

Now it’s really starting to look like a product, and not just some scraps of fabric!

Next up, take your case lining (a simple rectangle the full size of the case, with nothing to fold or hem. Sew a strip of velcro 2cm in from the right edge. Then take your pocket construction and pin it to the lining. You want to sew all along the bottom edge, up the left side and along the top, where the notepad pocket and flap meet the top edge. You can see it’s important here that your small top left pocket isn’t too tall, otherwise it would end up getting sewed in here too. Sew close to the edge so that all these stitches will be covered up by the final edging.

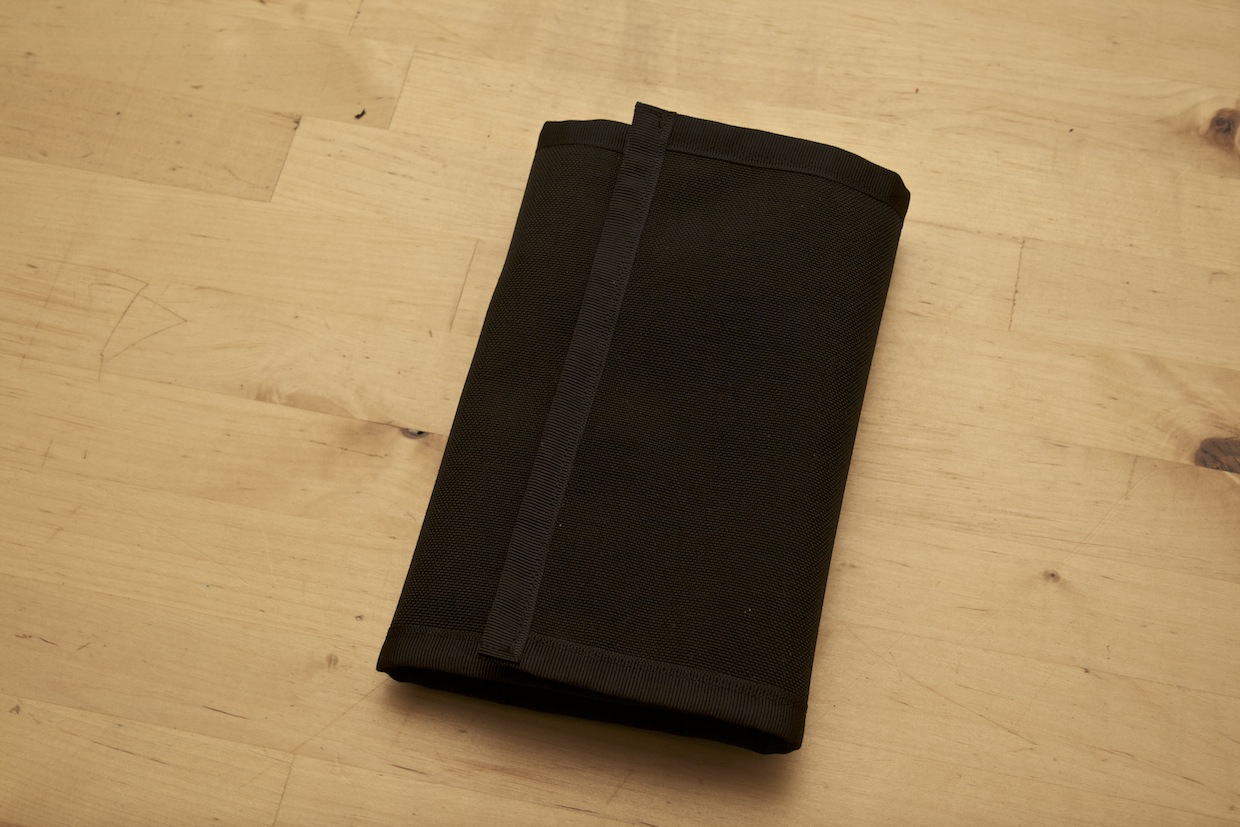

Step 6: Outer case and final assembly

Take your casing fabric and sew a couple of strips of velcro (I used the soft ‘loop’ part here on the outside, and the rougher ‘hook’ part on the lining). A couple of strips are useful to give you some flexibility in how tightly you shut the case.

Then pin your lining to the outer fabric and sew around all four sides. Trim off any excess and straighten the edges before applying the finishing ribbon.

Attach the trim (I used 25mm nylon grosgrain ribbon) along each edge, being careful to enclose all the existing edge stitching within the trim. Its easiest to attach the ribbon to one side, then fold it and sew again to attach the other side.

This picture show the top edge finished, and the bottom edge pinned and ready to go on the first side.

Because the ends of the ribbon fray, allow plenty of excess when attaching it. The top and bottom pieces can be trimmed to fit once they’re attached because their ends will be covered up by the left and right pieces. For these two, I hemmed the end of each before attaching it, to keep the ends neat. I believe the proper way to do this is with “mitred corners”, a technique commonly used by quilt-makers. Now I know.

Finished!

What I’ve learned for next time

I really enjoyed this project. It was very satisfying to be able to fabricate something with this quality of finish. This would be perfectly acceptable as a commercial product.

I could reach that level of finish because it is a very simple design: 2 dimensional, all straight lines. So I would like to learn more about 3D construction, and try to match this level of quality in a more complex design.

The case has fared well in use, though there are some things I would do differently for a future version:

- I’d like to try a way of including some minimal padding. I think this could work well when I chuck it in a bag to take it somewhere.

- The pen pocket is a bit too tall, making it tricky to pull pens out

- The notepad pocket behind the main pen pocket tends to flare out when the pen pocket is full. Not really a problem, but something like a zip here would really help with this.

- I’m not convinced by the small pockets. I use them to store a pencil and eraser, and I would like to have place to keep these things, but the very small pocket isn’t secure enough, and the mesh pocket is a bit too much of a compromise.

- I’d like to try out some different fabrics, and maybe do a version without ribbon trim.

I hope this walkthrough is useful to others. If you make something based on this design, do let me know.